Tumtec question: how many splicing steps? How to operate fusion splicer correctly?

How to protect fusion splicer in order to prolong life-span?

How do communicators properly protect their work partners

For fiber fusion splicer, "do things the right way, do the right thing."

Tumtec science lesson - correct use of fiber fusion machine.

In our life, a variety of products emerge one after another, but few of them is long service life. If a product wants to live a long life, not only the quality of the product itself, but also the correct use is very important.For communication engineers, more contact products should be the fusion splicer, optical fiber fusion splicer is high-tech mechanical products, comprehensive properties of this products is relatively high, so how is the correct use of optical fiber splicing steps?Let's take a look at the Tumtec fusion splicer!

The first step is to prepare the optical fiber

Before fiber splicing, fiber preparation requires three steps:

1. coating stripping

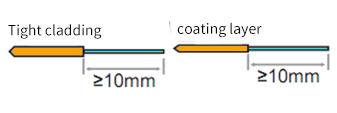

At least 50mm of coating is left after stripping the sheath (loose sleeve fiber is the same as tight sleeve fiber).Remove the coating layer with stripper, the length is 30~40mm.

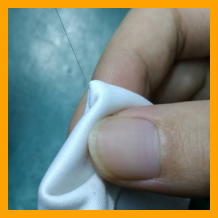

2. clean the fiber with a cotton paper dipped in alcohol.

3. fiber cutting

Use highly sophisticated cutting tools to cut the fiber.In order to ensure the quality of splicing, high precision cutting cleavers, such as T9 series optical fiber cleavers, should be used for cutting, and the length of optical fiber cutting should be strictly controlled (as shown in the figure on the right).

Note: remember to wear heat-shrinkable sleeve when fiber pretreatment

Important!

Make sure the bare optical fiber and its cutting surface are not dirty.

-

- avoid shaking the optical fiber in the air

- check whether the v-shaped groove and pressure hammer are clean. If not, clean it with a cotton swab dipped in alcohol

Conduct automatic fiber inspection

After the fiber is loaded into the fusion splicer, start the machine. Before splicing, it will automatically do discharge cleaning. After discharging cleaning, check the cutting Angle of each fiber and the quality of cutting end face.If the measured cutting Angle of the optical fiber is greater than the set limit value, or the end face of the optical fiber is found to have burrs, the buzzer will alarm, and the display will pop up a prompt box to remind the operator.

Start splicing operation steps

(1) open the splicer electromechanical source, when only splicing labeled SM fiber (itu-t-g. 652), recommended [SM Mode] Mode;

(2) confirm splicing and heating modes. When splicing different types of optical fibers, recommend [Auto Mode] Mode, but the splicing speed will be a little slower;

③

Clean fiber coating or tight sleeve

Insert the fiber into the heat-shrinkable protective sleeve;

④

Peel the fiber and clean the fiber

Pure alcohol with a concentration of more than 99%

Make sure that the coated residue or other dirt has been removed from the stripped fiber

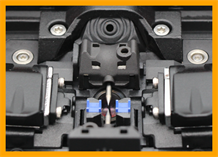

(4) put the fiber into the fixture

place the electrode between the edge of the v-groove and the central position of the bipolar electrode rod connection

Note: do not slide the fiber along the v-groove. The cutting surface of the fiber should be beyond the v-groove position, but not beyond the tip of the electrode rod

Place the electrode on the edge of the v-shaped groove and

The two poles are connected between the central positions of the electrodes

6. Cover the windproof cover to start automatic welding

The LCD screen can be viewed during splicing

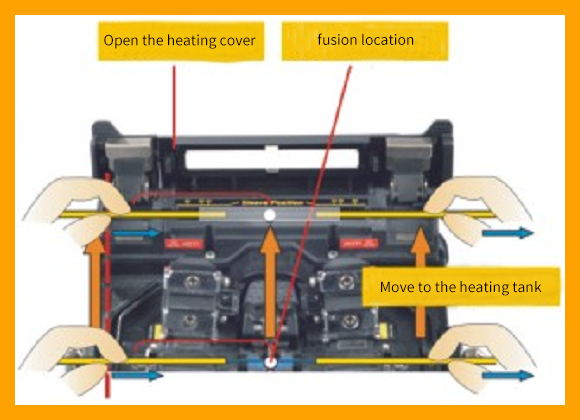

7 .Remove the fused fiber

Move the heat-shrinkable tube in the middle of the heating furnace

The optical fiber keeps the fusion contact at the center of the heat-shrinkable sleeve

Cover the heater and start heating

⑧ Finish

Note: in case of large splicing loss or large change in the altitude of the environment, [stable electrode] and [discharge correction] must be performed before splicing. If you need more information about this, pls see the previous contents which release by Tumtec!

Links

Magic Lamp