We are very concerned about what kind of fiber fusion machine for our own, what brand is good. However ,the best splicing machine if not maintenance, is in the cost of money, a waste of resources.Today, tumtec take you to understand the importance of splicing machine maintenance.

Fisrt: Why should the splicing machine be maintained and how often?

splicing machine is a set of optical, mechanical, circuit of high precision instruments, especially in the process of daily use dirty environment using dust is inevitable, clastic and fiber enter into equipment, optical system and electrode, stuck motors, corrosion circuit, etc., lead to optical fiber identification, splicing loss bigger, discharge is not stable, splicing quality, splicing time, reduce work efficiency, etc. With the increase of service life, the initial position and accuracy of motor and mechanical parts will be deviated. If not maintained in time, the aging of internal components will be accelerated and the service life of the equipment will be affected.

If you encounter the above mentioned problems should consider whether the machine is to do maintenance, the normal frequency is about 1 year to do a maintenance can, if the equipment use frequency is high or the environment slightly can shorten the maintenance cycle.

Good equipment maintenance can make your machine at least a few more years of money, and is efficient money, no one wants to use two or three years to change a new equipment, all the money to buy a machine to play. Car everybody knows to want on time maintenance, this money making money printing machine needs maintenance more.

Second:What do the maintenance of splicing machine do and what problems can be solved?

1. Cleaning:

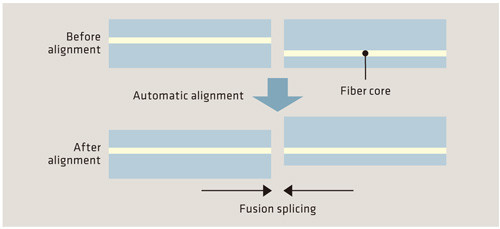

The cleaning of optical system, including objective lens, CCD (need to disassembly), reflector, LED, etc., can solve the problems of fuzzy optical imaging, dark background, slow core alignment, dirty optical fiber, wrong identification of optical fiber type, large splicing loss, bubble, etc.

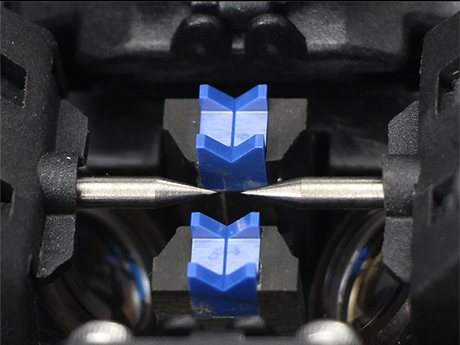

The electrode cleaning can remove the oxide on the surface of the electrode by grinding the electrode, which can solve the problems of over-discharge, over-discharge instability, over-discharge, over-weak discharge, deformation of splicing fiber, over-coarse and over-fine, and insufficient splicing intensity, etc. It can also increase the service life of the electrode by 1-2 times, and save the replacement cost of consumables.

V-groove and pressure foot cleaning, can solve the problem of abnormal optical fiber position, optical fiber Angle is too large, motor out of travel, long time to shaft.

Internal cleaning of the equipment (need to disassemble), can solve the broken optical fiber jam motor, circuit board corrosion, low accuracy to the shaft, splicing loss, extend the service life of the equipment, etc.

2. Equipment debugging

Equipment state adjustment, motor initial position adjustment, motor correction, discharge correction, stable electrode, software upgrade, can improve splicing quality and reduce the core time.

3. Old parts replacement, etc.

If you can not solve their own equipment fault, must not mess, splicing machine precision is micron, a little misoperation will be difficult to adjust. If you encounter problems you can't fix, you must find the after-sales department. Rattan you splicing machine has five exclusive services: 24-hour technical questions online answer, exclusive pre-sales consulting, sales training, after-sales maintenance services, three-year warranty service; A full range of professional service personnel to provide product consulting, product training, technical support.

Well, splicing machine maintenance of the importance of everyone should know it.

Links

Magic Lamp